Note: this article was originally published in 2022 and has been updated for accuracy and comprehensiveness in June 2024.

A crane load chart is an essential tool for crane operators to calculate a crane’s lifting capabilities. This chart ensures the crane does not exceed its lifting capacity, accounting for variations in lift capacity based on distance and angle. Factors like boom length, boom angle, and load radius are critical in determining a crane’s load capacity.

Contact TET for Crane Load Testing Services

What is Crane Load Testing?

Crane load testing is a critical safety procedure mandated by OSHA to verify a crane’s ability to handle its rated capacity. It ensures the crane can safely manage its maximum designed weight, preventing accidents and injuries. Load testing is required for both new cranes before their initial use and for cranes that have undergone modifications or significant repairs.

Importance of Crane Load Testing

By prioritizing regular crane load testing and investing in comprehensive mobile crane operator training, workplaces can significantly enhance the safety and efficiency of their crane operations. Testing of crane loads:

- Ensure equipment integrity and safe operation, reducing the risk of accidents and injuries.

- Instill confidence in crane operators by verifying equipment functions properly under its rated load.

Crane Load Testing Standards

The testing process adheres to ANSI B30 standards, specifically:

- B30.10 (hooks)

- B30.20 (below-the-hook lifting devices)

- B30.16 (overhead hoists)

During the test, technicians assess the load capacity of the lifters, hoists, and hooks. Following the test, the equipment undergoes a rigorous inspection to identify any potential defects that could compromise safety. A detailed report is then generated outlining the test results for future reference.

Frequency of Crane Load Testing

The frequency depends on several factors:

- Initial use: Before any operation

- Usage frequency: More frequent use requires more frequent testing

- Repairs/maintenance: Testing ensures continued safe operation after repairs

Water Bags for Crane Load Testing

Water bags have emerged as a safe and cost-effective method. These bags can be adjusted to various weights, allowing for multiple load tests without needing separate weights for each test. Importantly, water bag testing meets OSHA standards and can be used for all crane types.

Get Crane Load Testing Services

How to Read a Crane Load Chart

Crane load charts have a number of variations depending on the several factors that are related to the information of the lift capacity of the crane, the lift range, boom angle, and more. Here are the major factors that are required to understand a crane load chart.

Lift Capacity

The lift capacity measurement of a crane tells us how much load a crane can lift naturally, including the dimension of the load, lift height, and lift angle. The average crane can lift between 10,000 and 60,000 pounds.

Lift Range

The load chart diagram will illustrate the required boom length with the given lift distance and height.

Boom Angle

The boom angle is placed between the longitudinal and centerline of the boom and the horizontal centerline. A crane may lose balance when lifting a weight larger than the angle supports.

Movement

Cranes must frequently move or rotate in order to complete a lift. When determining the feasibility of a lift, it is necessary to consider how far and how fast a crane should rotate. Some lifts necessitate a full 360-degree turn by the crane. If movement is not taken into account, the crane may lose balance and tip over.

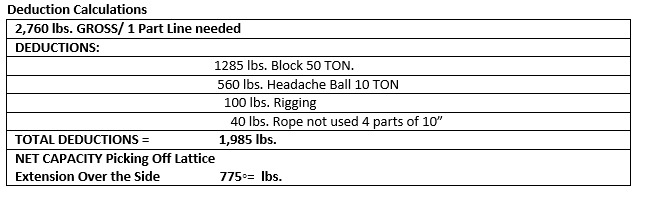

Deduction

To determine the amount of weight a crane can lift, the weight of the crane and its accessories should be deducted from the total weight. The accessories for a crane include:

- The rigging,

- The line

- The ball and jib

- The block

- The windspeed and windsail

The net capacity of a crane is dependent upon the nature of the lift and what capacity deductions need to be subtracted from the gross capacity. Examples of capacity deductions can include the weight of the main load block, the weight of the headache ball, the weight of the jib, the weight of all hanging cables, the weight of all rigging materials, and the weight of the load that is being lifted.

What Is the Bold Line on the Crane Load Chart?

A bold line divides most load charts in half, which shows the separation of structural strength and stability. All capacities listed on one side of the line are limited by the structural strength of the crane, while those listed on the other side are limited by the stability of the crane.

Total Equipment Training offers additional crane education resources.

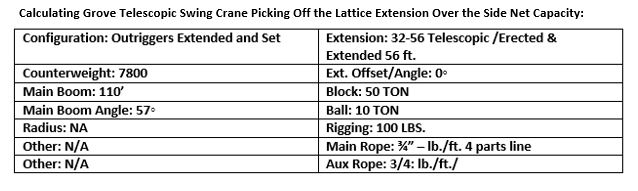

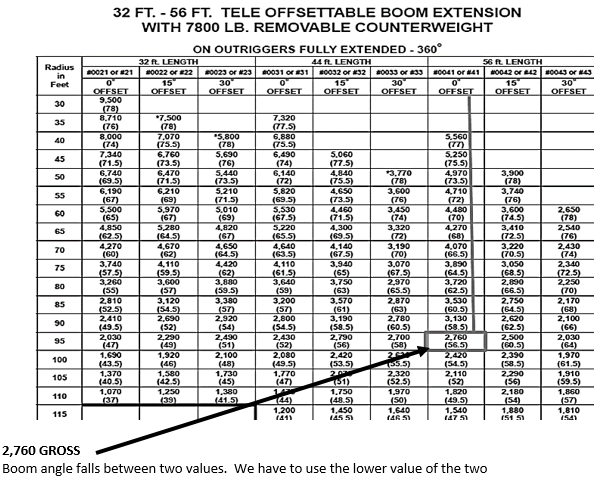

Below is an example on how to read a load chart.

Understanding a Load Chart

According to OSHA, every Crane Operator must know and understand how to interpret a load chart and the crane’s load chart must be on the crane at all times and consulted before each lift. It is not permitted to guess or mathematically calculate in-between chart values.

Contact TET to schedule additional crane training: (610) 321-2679

Creating a Safe Lift Plan: A Guide to Preventing Hazards

Lifting operations, involving materials, people, or equipment, pose various safety risks. To ensure a safe operation, a well-structured lift plan created by qualified personnel is crucial.

What a Lift Plan Should Include:

- Equipment: Specify the lifting equipment (cranes, forklifts, etc.) and their capacity to handle the load weight and any additional forces.

- Steps involved: Outline each step of the lift, from setup to completion.

- Personnel: Identify required personnel and their roles (operators, signalers, supervisors).

- Objectives: Clearly define the goals of the lift operation.

- Hazard assessment: Identify potential hazards and outline mitigation strategies to protect workers, equipment, and surrounding structures.

Key Considerations for Safe Lifting:

- Strength and Stability: Lifting equipment and components (slings, cables) must be strong enough to handle the load and any unexpected conditions (weather changes).

- Positioning and Installation: Carefully consider the positioning of lifting equipment to avoid hazards like power lines, structures, or worker proximity. Ensure the load is securely attached to prevent detachment or movement.

- Emergency Protocols: Establish clear procedures for equipment failure scenarios to minimize damage and injury.

- Supervision: The level of supervision should match the complexity of the lift and personnel skill levels. Complex lifts require more oversight.

- Working under Suspended Loads: Generally, avoid placing personnel under suspended loads. Refer to OSHA guidelines for exceptions and rigging requirements.

- Environmental Factors: Account for potential weather disruptions like wind, rain, or fog that could impact lift stability or visibility.

Contact Total Equipment Training to schedule your heavy equipment inspections, training, and more!