Note: This comprehensive guide aims to provide you with a one-stop resource for all your mobile crane inspection needs. Much of this crane safety content consists has been consolidated from our previous blogs; and Total Equipment Training has incorporated the latest updates regarding crane inspections to ensure accuracy and relevance. If you have any questions on mobile crane inspections, please call the experts at Total Equipment Training: (610) 321-2679.

Table of Contents

- Importance of Mobile Crane Inspections

- OSHA Crane Inspection Requirements, Compliance and Regulations

- Types of Mobile Crane Inspections

- Crane Load Testing

- Mobile Crane Inspection Frequency

- Conducting a Thorough Crane Inspection

- Mobile Crane Safety and Training

- Benefits of Using a Third-Party Inspector for Crane Inspections

- Best Practices for Safe Mobile Crane Operation

- Total Equipment Training’s Comprehensive Crane Inspection Solutions

Schedule Your Mobile Crane Inspection Today!

The Importance of Mobile Crane Inspections

Mobile cranes are the workhorses of construction sites, but their daily use can lead to wear and tear, potentially causing accidents and injuries. To prevent these issues, regular and professional crane inspections are crucial for identifying potential problems before they occur. These inspections keep everyone safe and ensure the crane functions optimally.

Regular inspections offer a multitude of benefits. First and foremost, they play a vital role in accident prevention. By catching minor issues before they escalate into major breakdowns or accidents, inspections protect workers and property from harm. Inspections also enhance safety by identifying and addressing potential hazards, creating a safer work environment for everyone on the job site. Finally, regular inspections help ensure the crane is functioning properly for maximum efficiency and productivity. A well-maintained crane experiences fewer breakdowns, delays, and costly repairs, ultimately leading to a more productive work site.

Read more about the newest OSHA Crane Compliance Directives on our blog.

OSHA Crane Inspection Requirements, Compliance and Regulations

Mobile cranes play a pivotal role in enhancing lifting operations across diverse work sites, facilitating efficiency and productivity. However, a concerning trend persists: many crane operators and their employers demonstrate inadequate competence in safely executing crane operations. This deficiency often stems from a lack of training and familiarity with the regulations, protocols, and safety procedures mandated by authoritative bodies such as OSHA (Occupational Safety and Health Administration).

The Occupational Safety and Health Administration (OSHA) enforces a set of regulations to ensure the safety of workers operating or working near cranes. These regulations aim to minimize accidents and injuries by mandating thorough and regular inspections.Here’s a breakdown of OSHA’s key crane inspection requirements for compliance:

Competent Person Definition: Whose Job Is It To Inspect Cranes at the Jobsite?

While OSHA allows employers to designate a qualified employee as a competent person for annual inspections, the definition of “competent person” is crucial [4]. An OSHA interpretation clarifies that a competent person must have “knowledge and understanding of crane operation, capacity limitations, and the applicable OSHA standards.” This emphasizes the importance of ensuring the designated inspector possesses the necessary expertise to conduct a thorough and effective inspection.

While OSHA allows employers to designate a qualified employee as a competent person for annual inspections, the definition of “competent person” is crucial [4]. An OSHA interpretation clarifies that a competent person must have “knowledge and understanding of crane operation, capacity limitations, and the applicable OSHA standards.” This emphasizes the importance of ensuring the designated inspector possesses the necessary expertise to conduct a thorough and effective inspection.

Engaging a third-party inspector for crane inspections offers several benefits, including impartial reporting, specialized expertise, cost-saving recommendations, enhanced confidence through credentials, and adherence to state regulations. TET, a nationally recognized, OSHA-compliant organization, stands ready to provide third-party inspection services for mobile cranes and heavy vehicles, ensuring thorough and meticulous assessments.

Record Keeping and Documentation

Employers are obligated to maintain documentation of all crane inspections. These records should detail the dates of inspections, the identity of the inspector performing the inspection, and any findings or corrective actions taken.

Maintaining thorough and readily available documentation of these inspections acts as a safety net, providing a clear history of the crane’s condition and any identified issues.

What needs to be documented?

OSHA regulations mandate that employers retain specific details from crane inspections. These details include:

- Dates of Inspections: Keeping a clear record of when inspections were conducted helps maintain a consistent schedule and avoid missed inspections.

- Inspector Identification: Documenting the inspector’s name ensures accountability and demonstrates the inspector’s qualifications.

- Inspection Findings: Any issues identified during the inspection should be clearly documented. This allows for proper follow-up and ensures no critical details are overlooked.

- Corrective Actions: Record the actions taken to address any problems identified during the inspection. This demonstrates a commitment to resolving safety concerns.

Pre-Inspection and Collaboration:

Prior to a formal inspection, a qualified inspector will typically:

- Review Past Records: Past inspection and maintenance records provide valuable insights into the crane’s overall health and any recurring issues.

- Consult the Manual: The manufacturer’s operator manual serves as a crucial reference for proper operation, capacity limitations, and inspection procedures. OSHA mandates that a copy of the manual is always present in the crane cab for easy access by the operator.

- Discuss Capacity and Restrictions: Open communication with the crane operator allows the inspector to understand the crane’s usage, any site-specific limitations due to ongoing activities, and potential functional limitations of the crane itself.

Record Retention Requirements:

OSHA regulations require employers to retain specific inspection records within the crane itself. These records should detail any deficiencies found and the subsequent corrective actions taken. While indefinitely storing all records may be a best practice, OSHA acknowledges that keeping the last two inspection and maintenance records fulfills the intent of the standards.

By maintaining comprehensive and accessible crane inspection records, employers demonstrate their commitment to safety and establish a clear history of the crane’s condition. This not only safeguards workers but also serves as valuable evidence in case of any incidents.

Types of Mobile Crane Inspections

Mobile cranes come in various configurations, each with specific strengths and uses. To ensure their safety and functionality, all cranes require regular inspections. Here’s a breakdown of common crane inspections, categorized by type and application:

Mobile CranesCrawler CranesThese unique mobile cranes utilize tracks for superior traction on uneven surfaces. While highly maneuverable on site, they require transport between jobs. Crawler crane inspections follow the same protocols as other mobile cranes. All-Terrain Mobile CranesThese powerful, multi-wheeled cranes are known for their lifting capacity (40 to 1000 tons) and long operating times. Inspections for these cranes are similar to those for other mobile cranes. |

Rigging Equipment InspectionRegardless of crane type, regular inspections of slings, shackles, and hooks are essential for preventing accidents and ensuring load security. These inspections are typically incorporated into routine mobile crane inspections |

Hoist InspectionsAs critical components, hoists require regular inspections to detect wear, damage, or malfunctions. These inspections typically check mechanical and electrical components, brake systems, and load capacity. |

Overhead Cranes (Fixed Runway)Inspections ensure safe operation and compliance with safety standards. They typically cover trolleys, bridge structures, electrical systems, and hoists. |

Bridge CranesSimilar to overhead crane inspections, bridge crane inspections meticulously assess the condition of structural components, electrical systems, hoists, and mechanical parts. Regular inspections help identify potential issues and ensure optimal performance. |

Gantry CranesCommonly used in construction and shipbuilding, gantry crane inspection ensure structural integrity, proper functioning of trolleys and hoists, and compliance with safety regulations. |

Crane Load Testing

Crane load testing is an essential safety measure mandated by OSHA for all lifting equipment, including mobile cranes. It goes beyond visual inspections to ensure the crane functions reliably and safely under stress. The test verifies that all components subjected to strain during lifting operations perform properly. It also helps identify parts most susceptible to wear and tear during regular use.

- Manufacturers specify load limits for various configurations of the mobile crane being tested.

- Certified inspectors conducting the load test will push these limits to establish the maximum safe working load (never to be exceeded during operation). This overload typically ranges from 20-25% of the rated load capacity.

- The test results provide valuable data to determine the crane’s operational limitations and ensure it stays within safe working parameters.

Schedule Crane Inspection Services

Mobile Crane Inspection Frequency

Mobile crane inspections are crucial for safety and functionality. ASME and OSHA regulations establish four main types of crane inspections, each designed to address specific needs:

- Initial Inspection: This comprehensive inspection is mandatory for new cranes, reinstalled cranes, or cranes that have undergone significant modifications. A thorough examination is conducted to ensure the crane meets all safety standards and operates as intended before any lifting tasks begin.

- Daily Inspections: OSHA daily crane inspection requirements should be performed by the crane operator at the start of each shift, these inspections focus on readily visible components for signs of damage or wear. The operator checks for leaks, loose parts, and any malfunctions in the crane’s control systems. This quick but crucial inspection helps identify any immediate problems that could impact safe operation. Total Equipment Training provides a FREE Daily Crane Inspection Checklist for you to download.

- Monthly Crane Inspections: Conducted by a competent or qualified person (ideally a qualified inspector). These are more thorough than daily inspections and examine a wider range of components, including hydraulic systems, electrical components, and the structural integrity of the boom and jib.

- Annual Crane Inspection: Performed by a qualified crane inspector with certified mobile crane training. This comprehensive examination analyzes all crane components to ensure long-term safety and operation.

Who Can Perform Mobile Crane Inspections?

The qualifications required for the inspector depend on the inspection type:

| Daily Inspections: A competent person (operator, supervisor, etc.) can perform these inspections with the help of a crane inspection checklist. Since these inspections focus on readily visible components, someone familiar with the crane’s operation can effectively identify any immediate issues. | Monthly Inspections: A competent or qualified person can perform these inspections. However, to ensure a more thorough examination, it’s highly recommended to use a qualified mobile crane inspector who has the expertise to identify potential problems that a less experienced inspector might miss. | Annual Inspections: Only a qualified mobile crane inspector with certified mobile crane training can perform these inspections. These inspectors have the most in-depth knowledge and training to conduct a meticulous examination of the entire crane. |

Conducting a Thorough Crane Inspection

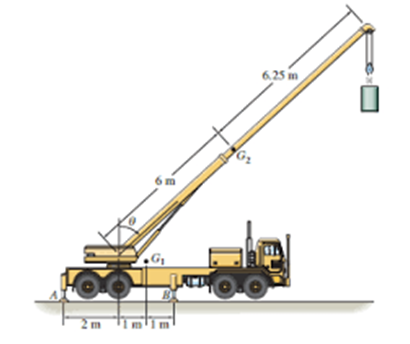

Before conducting a crane inspection, it’s crucial to assess operational factors such as load capacity, site restrictions, and the crane’s setup. Understanding key principles like center of gravity and stability aids inspectors in identifying potential issues. Pre-inspection tasks include reviewing maintenance records, operator manuals, and consulting with the crane operator.

The core of crane safety lies in a detailed examination of its components, including the cab, structure, and wire ropes. Inspectors closely inspect for wear, damage, leaks, and structural integrity. Observing the crane in motion is essential to detect any potential failures. A full-range test without a load helps identify abnormal movements or sounds.

Mobile Crane Inspection Process

Professional mobile crane inspectors meticulously examine various crane components to ensure safe operation and compliance with regulations. Here’s a breakdown of the inspection process:

- General Condition: Visual inspection for leaks, damage, and proper guarding of moving parts.

- Operator’s Cab: Check controls, instruments, and load charts for functionality.

- Lifting Mechanisms: Scrutinize sheaves, drums, hooks, and wire ropes for wear and tear.

- Stability and Braking Systems: Verify outrigger functionality and braking system performance.

- Structural Integrity: Examine the boom, jib, attachments, and mainframe for cracks or corrosion.

- Hydraulic Systems: Check hoses, fittings, and tubing for signs of wear or malfunction.

- Electrical Components: Inspect for signs of wear or malfunction to prevent unexpected shutdowns.

Ensure compliance with OSHA regulations by checking the following:

- Manufacturer Operating & Maintenance Manuals: Must be present in the cab for reference.

- Guarding: Exposed moving parts must be guarded or isolated to prevent injuries.

- Swing Clearance Protection: Materials to guard the rear swing area are required.

- High Voltage Warning Signs: Installed in the cab and on the crane exterior.

- Boom Stops and Jib Boom Stops: Shock absorbers or hydraulic mechanisms to prevent overturning.

- Boom Angle Indicator and Boom Hoist Disconnect: Readable from the operator’s station for accurate control and to shut off or stop the boom hoist at designated angles.

- Two-Blocking Devices and Power-Controlled Lowering: Required for telescoping booms and cranes lifting personnel, ensuring safe operation and preventing malfunctions.

- Leveling Indicating Device: Ensures the crane is level for safe operation.

- Sheaves and Main Hoist & Auxiliary Drum System: Inspected for smooth grooves, no cracks, proper flange condition, and minimum wrap requirements on the drum.

- Main Boom, Jib Boom, and Boom Extensions: Checked for cracks, corrosion, tight bolts and rivets, and documented certification if boom members have been repaired.

- Load Hooks and Hook Blocks: Labeled with rated capacity, counterweighted, and free of cracks or excessive wear. Hooks used for personnel lifting must have effective safety catches.

- Hydraulic Hoses, Fittings & Tubing: Examined for leaks, blistering, abrasion, or damage.

- Outriggers: Verified for proper function, visibility to the operator, and compliance with manufacturer specifications.

- Load Rating Chart: Must be durable, with legible letters and figures, accessible to the operator at the controls.

- Wire Rope: Inspected for broken wires, excessive wear, and external damage.

- Braking System: Depending on the crane type, a service brake system, secondary emergency brake system, parking brake system (rubber-tired cranes), or brakes/locking devices (crawler cranes) are assessed to ensure they function properly and meet grade requirements.

- Turntable/Crane Body: Rotation point gears and rollers are checked for damage, wear, and proper adjustment. Components should be securely locked and free of cracks. The swing locking mechanism must be functional and operational from the cab.

- Counterweight: Must be approved, installed according to manufacturer specifications, and have secure attachment points.

Get Professional Mobile Crane Inspection

Mobile Crane Safety and Training

Both employers and employees bear responsibility for preventing avoidable crane accidents and fostering a safe work environment. Investing in comprehensive training is paramount to achieving this goal. Total Equipment Training will come to YOUR worksite, and train YOUR employees on YOUR equipment.

Get Company Training for Mobile Crane Operators

Many accidents documented by OSHA stem from ignorance and negligence, potentially leading to costly penalties, reputational damage, and even business closure. TET not only offers crane operator training but also conducts comprehensive inspections. Prioritizing regular inspections is essential for maintaining safety and operational efficiency. Employers and site managers should enlist the services of professional, OSHA-certified inspectors to ensure compliance and mitigate potential hazards.

To avoid becoming a statistic, seek professional training from industry experts dedicated to delivering high-quality instruction. Total Equipment Training (TET) stands as a reliable partner in this endeavor.

Mobile Crane Operator Training

TET’s Mobile Crane Operator Training empowers crane operators with the requisite skills to execute their duties safely and efficiently. This program enhances participants’ proficiency in pre-use crane inspections, signal person hand signals, interpretation of manufacturer manuals (including load chart testing), and compliance with OSHA safety regulations.

TET offers tailored group training programs for mobile crane operators at all skill levels, from novices to seasoned professionals seeking refresher courses. Delivered by experienced crane operators and endorsed by the National Commission for the Certification of Crane Operators (NCCCO), this training program ensures comprehensive preparation, facilitating swift certification and enabling participants to return to work promptly.

Additionally, TET provides resources for Rigger Training and Signal Person Training, equipping entire mobile crane crews with synergistic skills to enhance efficiency while upholding stringent safety standards.

Benefits of Using a Third-Party Inspector for Crane Inspections

According to the Crane Manufacturers Association of America (CMAA), crane inspectors must possess over 2,000 hours of field experience, supplemented by formal training in safety codes, crane operations, report writing, and crane functioning. Their expertise is vital for ensuring safe crane operations.

3rd Party Crane Inspector Benefits:

For enhanced safety and peace of mind, consider utilizing a 3rd party crane inspection service. These inspectors offer unbiased reports, free from internal influences that might compromise objectivity. Their area of expertise is solely focused on crane inspections, translating to a highly specialized approach that can uncover potential problems a less experienced inspector might miss.

Additionally, Total Equipment Training’s experienced trainers can identify areas for improvement in your crane use, potentially leading to cost savings and increased productivity. Our certifications inspire confidence in both managers and operators.

How Much Do Crane Inspections Cost?

The cost of a crane inspection depends on several factors:

- Number of Cranes: The more cranes you have inspected, the higher the overall cost.

- Crane Capacity: Higher capacity cranes typically require more time and resources to inspect, leading to increased costs.

- Components Inspected: Inspections involving a wider range of components naturally take longer and cost more.

- Inspection Time: The complexity of the inspection and the number of components inspected determine the time required, impacting the cost.

- Environment and Accessibility: Inspections in hazardous or hard-to-reach locations necessitate additional safety measures or specialized equipment, potentially raising the cost.

By understanding these factors, you can better anticipate and budget for crane inspection expenses. Total Equipment Training offers in-person mobile crane inspections to the following areas:

Mobile Crane Inspection in PA | Mobile Crane Inspection in DE | Mobile Crane Inspection in MD | Mobile Crane Inspection in NJ

Best Practices for Safe Mobile Crane Operation

Crane safety is paramount. If anything feels off during operation, stop immediately and have a qualified professional inspect the crane. By following these guidelines and prioritizing safety, you can ensure a successful and injury-free mobile crane operation.

- Site Assessment: Before deploying the crane, assess the ground stability and ensure it can handle the crane’s weight. Secure the designated work area to prevent unauthorized access. Collaborate with geotechnical engineers if necessary.

- Daily Inspections: Develop a comprehensive checklist to conduct thorough crane inspections before each operation. Look for signs of wear, damage, or malfunctioning components. Only qualified personnel should perform these inspections. Refer to the manufacturer’s guidelines for specific procedures.

- Planning and Communication: Create a daily plan outlining the lifting tasks and considering factors like weather conditions, overhead obstructions, and ground stability. Ensure clear communication between the crane operator, signal person (if needed), and other workers on the site.

Operating the Crane Safely

- Qualified Personnel: Only trained and certified operators should operate the crane. They must be familiar with the manufacturer’s specifications, load charts, and safe operating procedures.

- Pre-Operation Checks: Double-check that the crane is on stable, level ground and within the safe working radius of any power lines. Ensure all outriggers are properly deployed on solid, level surfaces according to the manufacturer’s instructions.

- Load Rigging: Loads must be properly rigged using appropriate slings and securement methods to prevent them from becoming dislodged during lifting. Consider using a qualified rigger for complex lifts.

- Signal Person: For operations where the operator doesn’t have a clear view, a qualified signal person is crucial to guide the operator and ensure clear communication. Use standardized hand signals approved by OSHA .

Common Hazards and How to Avoid Them

- Falling Loads: The most critical risk is a load detaching and falling. Ensure proper rigging and avoid exceeding the crane’s capacity.

- Crane Toppling: Extending the boom can shift the center of gravity and cause a tip-over. Stay within the crane’s rated capacity and operate on stable ground.

- Electrocution: Never operate the crane near live power lines. If operating near them is unavoidable, ensure they are de-energized first.

- Unstable Ground: Soft ground can cause the crane to slip or buckle. Prior to deployment, assess the ground stability and use crane pads if necessary.

- Bad Weather: Strong winds can topple the crane, and wet weather can make surfaces slippery. Avoid operating the crane in harsh weather conditions.

Total Equipment Training’s Comprehensive Crane Inspection Solutions

Total Equipment Training offers a holistic approach to heavy equipment operator training. Our experienced crane inspection solutions are designed to ensure your equipment operates smoothly and securely, minimizing downtime and maximizing productivity.

Elevating Your Crane Inspection Program

We specialize in delivering the best crane inspection services that exceed industry standards. Here’s how Total Equipment Training can enhance your inspection program:

-

- Expert On-Site Inspections: Our certified inspectors meticulously examine all types of cranes, from mobile giants to overhead workhorses. We ensure your equipment meets all necessary safety standards and identify any potential issues before they become problems.

- Streamlined Reporting: We provide clear, concise reports that prioritize critical repairs and reference relevant OSHA regulations for easy understanding.

- Compliance Confidence: Regular inspections are essential for maintaining OSHA compliance. Our inspectors take the guesswork out of the process, giving you peace of mind knowing your equipment meets all safety benchmarks.

- Proactive Maintenance: Inspections aren’t just about catching problems; they’re about preventing them. By identifying wear and tear early on, you can schedule targeted maintenance to extend the lifespan of your cranes and avoid costly downtime.

Where Can I Get Mobile Crane Inspection Services?

Ensure the safety and longevity of your cranes by partnering with Total Equipment Training. We offer a comprehensive suite of crane operator training and inspection services, tailored to your specific needs. Don’t compromise on safety—invest in Total Equipment Training’s expertise and safeguard your assets.

Contact us today to discuss your inspection requirements and receive a personalized quote. Prioritize safety, efficiency, and peace of mind with Total Equipment Training’s unrivaled inspection solutions.