Study Materials for CCO and Heavy Equipment Training

Total Equipment Training proudly supports the national certification program provided by the National Commission for the Certification of Crane Operators (CCO) and offer comprehensive training to equip candidates for success in both the written and practical exams. Let Total Equipment Training help you get CCO Certification! Explore our range of CCO certification study materials, including extensive study manuals, practice exams, and more to aid your preparation.

CCO Crane Training Materials

Total Equipment Training offers the following Crane Training Materials for CCO Certification:

- Mobile Crane Certification Manual (Hard Copy and Digital Version)

- Core Exam Study Guide

- Practice Exams for Fixed Cab and Swing Cab

Mobile Crane Operator Training for CCO Certification

Our Mobile Crane Operator Training for CCO Certification includes a core examination that covers site, operations, technical knowledge, and load charts. To attain CCO mobile crane operator certification, candidates must pass two pivotal exams.

Read our in-depth guide for the CCO Mobile Crane written exam.

CCO Rigger Level I Certification

Total Equipment Training offers the following Rigger Level 1 Training Materials for CCO Certification:

- General Knowledge Manual

- Practice Exams (with answer sheets)

Rigger 1 Training for CCO Certification

Obtaining CCO Rigger (Level I) certification involves passing a written and practical exam. The CCO Rigger Level 1 manual covers requirements for rigging personnel, policies, procedures, and various forms. The training focuses on the scope of rigging activities, recognizing rigging components, technical knowledge, inspections, rigging activity execution, and the importance of basic math skills. The exams also evaluate candidates on pre-use rigging inspections, rigging hitches, rigging connections, and basic knots.

This comprehensive program ensures that candidates are well-prepared to meet industry standards and achieve CCO Rigger Level I certification.

Read our in-depth guide for more about CCO Rigger Certifications

Signal Person CCO Certification

Total Equipment Training offers the following Training Materials for CCO Certification of Signal Persons:

- General Knowledge Manual

- Practice Exams (with answer sheets)

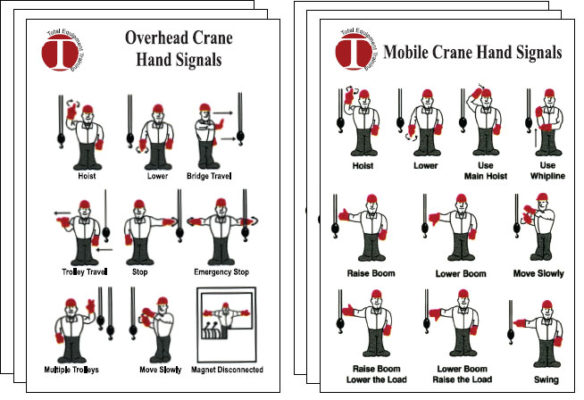

The Signal Person training for CCO Certification is designed around a comprehensive understanding of five signal domains, including hand signals, voice commands, fundamental crane operation knowledge, site-specific situational factors, and adherence to safety regulations and standards.

The CCO Signal Person manual provides insights into signal usage, common hand signals for mobile crane control, signal person requirements and qualifications, and voice signal communication protocols. This program ensures that candidates are thoroughly prepared for their certification.

Read our in-depth guide for more about how to become a CCO Certified Signal Person.

Free Mobile Crane Reference Card With Purchase

FREE with any crane, rigging, or signal person manual purchase from Total Equipment Training

One free digital wallet sized mobile crane hand signal pocket card and one free digital overhead crane hand signal pocket card. You can print out these cards as many times as you like. Share with friends and coworkers. Keep one handy for quick reference when needed in your crane directing duties. One set is a $12 value for each time you print them out..

About CCO Certifications

The CCO, established in 1995, is an independent, not-for-profit organization dedicated to creating and administering a nationwide certification program for crane operators. They are accredited by OSHA and ASME, ensuring that their testing standards meet the highest industry requirements.

CCO Certification stands as the “gold” standard in crane and crane-related personnel certifications. Many states now require CCO Certification as a prerequisite for obtaining licensing. CCO provides a list of reference materials to study for exam preparation, and it is the candidate’s responsibility to acquire and study these materials. Total Equipment Training has gathered these resources and organized them into easy-to-read mobile crane study guides.

In addition to our heavy equipment study materials, Total Equipment Training offers flexible in-person CCO training options to accommodate your needs.

Crane Operator Certification and Licensing Requirements

It’s crucial to distinguish between “licensing” and “certification” for heavy equipment operators. Licensing, the stricter of the two, is a governmental requirement for practicing a specific profession or occupation. This typically involves an examination, often alongside training and experience prerequisites. Certification is typically a voluntary process where individuals are acknowledged for their knowledge and skills. Certification only becomes mandatory when it forms the foundation of a state or federal licensing program, such as the CCO crane operator certification program or when employers and project owners make it a condition of employment.

Licensing Requirements

Currently, crane operators in 16 states and 7 cities face licensing requirements, subject to periodic administrative changes. It’s essential to stay updated by contacting the relevant authorities for the latest information. While Delaware currently does not impose licensing requirements for crane operators, it’s important to be aware of state-specific regulations.

States That License:

- California *

- Connecticut

- Hawaii *

- Maryland *

- Massachusetts

- Minnesota *

- Montana *

- Nevada *

- New Jersey *

- New Mexico *

- New York

- Pennsylvania *

- Rhode Island

- Utah *

- Washington *

- West Virginia *

Cities That License:

- Chicago

- Cincinnati *

- New Orleans *

- New York City *

- Omaha *

- Philadelphia *

- Washington, DC

(* Require or recognize CCO certification)

Empower Your Heavy Equipment Operators with CCO Certification

Our team at Total Equipment Training comprises CCO-certified mobile crane operators with extensive hands-on experience. And our CCO mobile crane certification training programs are meticulously tailored to meet the specific needs of your staff, ensuring they are well-prepared for both written and practical exams.

Whether it is for yourself, or your employees, purchase mobile crane operator study materials, rigger certification resources, and signal person certification materials today.

For additional information and inquiries, please reach out to our office at (610) 321-2679.